HD HYDROGEN

Family Site

Business Areas

Future Builder,

HD Hydrogen

As a Future Builder leading new future businesses, we focus on fuel cells and water electrolysis,

core technologies for carbon neutrality and hydrogen economy.

Growing as a specialized company

in SOFC/SOEC main equipment based on 3rd generation SO (Solid Oxide) technology, we are preparing to

enter the maritime and electrolyzer markets. We are accelerating business expansion and technological

innovation by acquiring Convion, which has unique technological capabilities in the SO field.

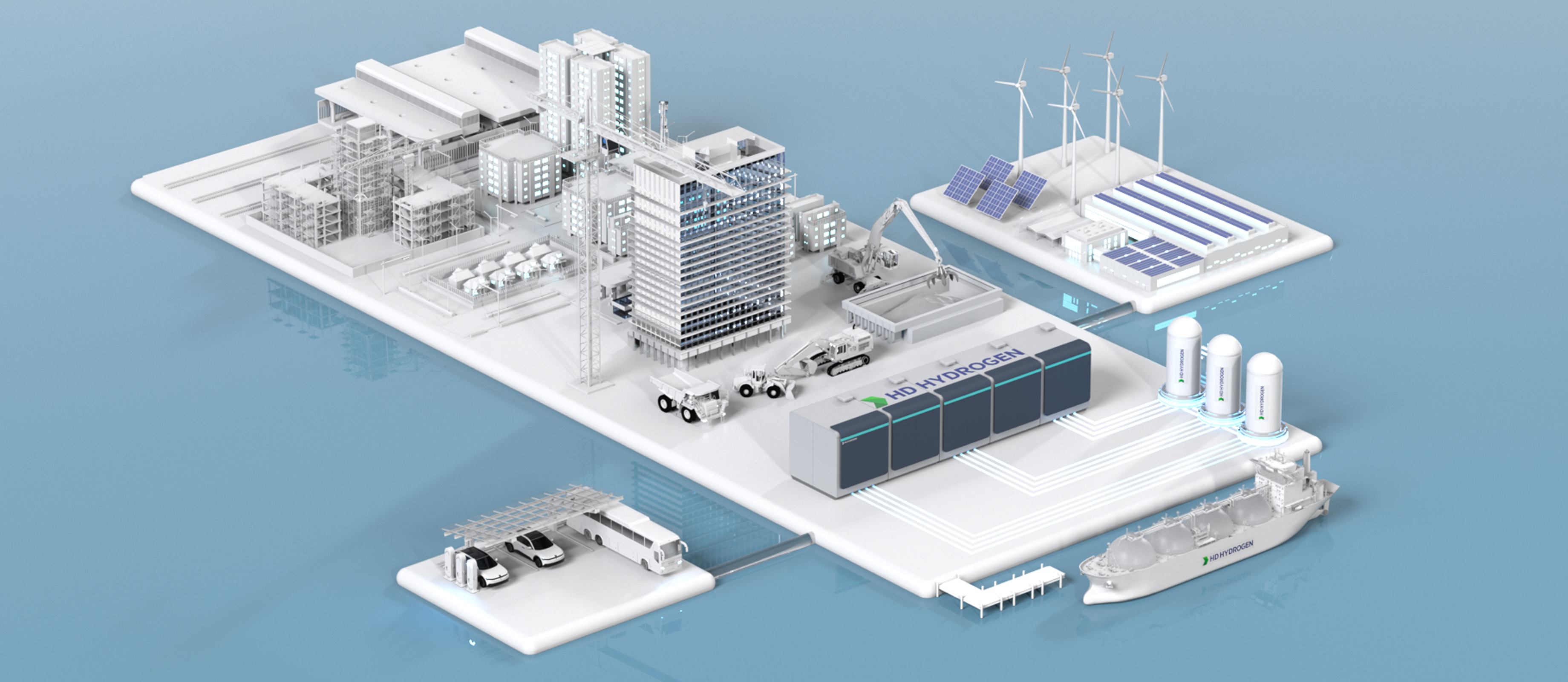

Stationary Power Generation

HD Hydrogen's solid oxide fuel cells are optimized for land-based power plants and distributed power supply based on high efficiency and stability. Achieving over 60% electrical efficiency and 80% total energy efficiency through waste heat utilization, they can be used in various applications, including large-scale power generation, data centers, industrial complexes, and commercial buildings. It provides a sustainable energy supply by minimizing greenhouse gas emissions.

-

Large-Scale Power Generation

-

Microgrid

-

Commercial Building

-

Data Center

-

Biogas

Marine

3rd generation solid oxide fuel cells are innovative solutions suitable for ships' main propulsion systems and auxiliary power supply. High-temperature operation enables the use of various fuels, dramatically reducing emissions compared to existing diesel engines, meeting IMO (International Maritime Organization) environmental regulations. HD Hydrogen's technology can be applied to large commercial vessels, cruise ships, and offshore platforms, leading the maritime industry's decarbonization through design that considers safety and space efficiency.

-

Propulsion

-

Auxiliary Power

-

AMP, Alternative

Maritime Power Supply

Electrolyzer

HD Hydrogen's solid oxide electrolyzer technology produces hydrogen at high efficiency by simultaneously utilizing electrical and thermal energy through high-temperature operation. This technology can economically produce 'green hydrogen' in connection with renewable energy and can be utilized in various fields, including industrial processes, energy storage, and transportation fuel.

-

Clean Hydrogen Power Generation

-

Industrial Hydrogen Production

A Sustainable Future Connected by Hydrogen

Designing the Energy Ecosystem from Production to Utilization

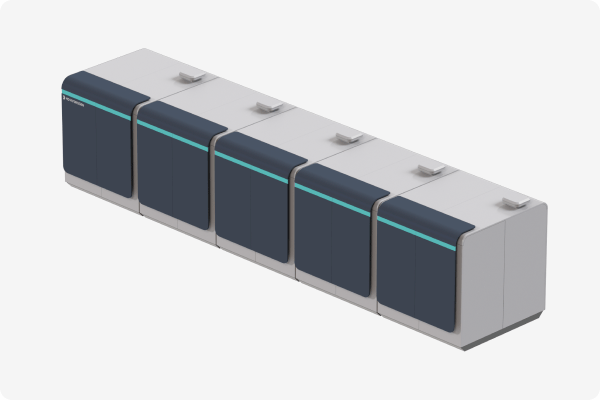

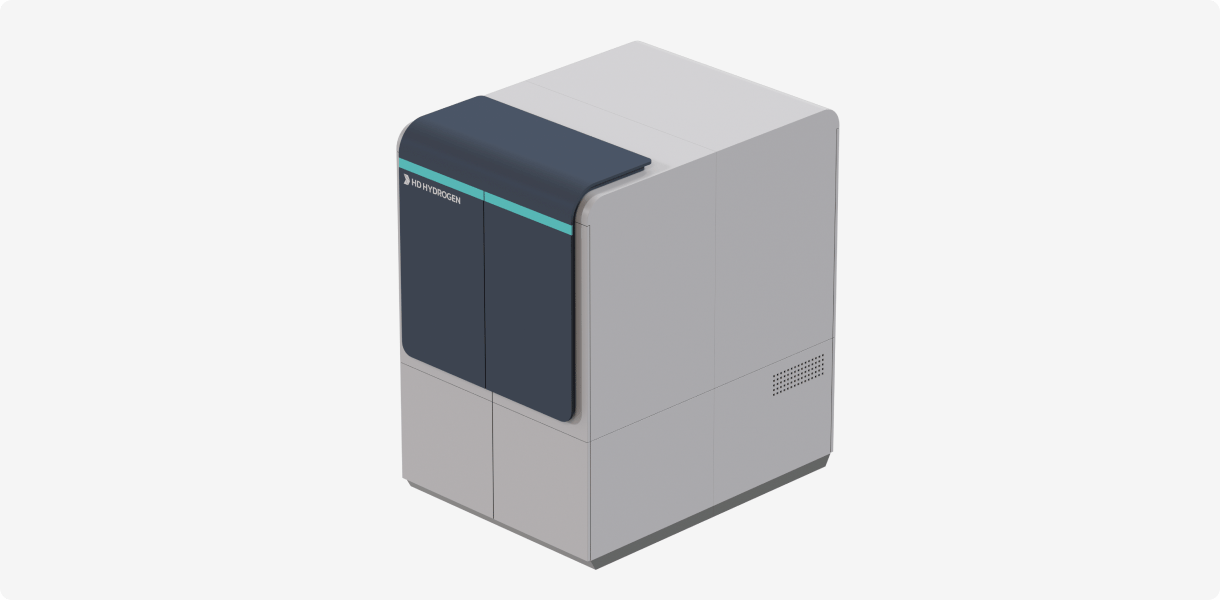

Next-Generation Large-Scale SOFC”

The HD300 is a large-scale power generation solution that embodies technological innovation in the field of Solid Oxide Fuel Cell (SOFC). It achieves up to 65% electrical efficiency in high-temperature environments and maximizes energy flexibility by utilizing a wide range of fuels, from natural gas to biogas.

Its compact design boasting high power generation density makes efficient operation possible even in limited spaces. A digital twin-based real-time control system ensures operational stability. It is an integrated distributed power system optimized for manufacturing, data centers, and smart cities requiring large-scale energy.

Specification

| Outputs | |

|---|---|

| Power output(net AC) | 285 kW |

| Voltage | 3ph, 380V |

| Frequency | 50/60 Hz |

| Inputs | |

|---|---|

| Fuel | Natural Gas |

| Input Fuel pressure | 4barg |

| Water | None during normal operation |

| Emissions | |

|---|---|

| Nox | ≤ 0.05 g/kWh |

| Sox | ≤ 0.07 g/kWh |

| CO | ≤ 20 ppm |

| VOCs | negligible |

| CO2@ nominal load, BoL | 330 [kg/MWhe] |

| Physical Attributes and Environment | |

|---|---|

| Weight(w/skid) | 28.8 ton |

| Dimensions(w/skid) | 12.6m(L) x 2.3m(W) x 2.5m(H) |

| Temperature range | -20°C - 45 °C (-4 °F to 104 °F) |

| Humidity | 0-100% |

| Seismic vibration | TBD |

| Location | Outdoor |

| Noise | <65 dBA @ 10 ft (3 m) |

| Codes and standards | |

|---|---|

| Safety | KESC, IEC 60079, IEC 62282 |

| EMC | KESC IEC 62282-3 |

| Grid Interconnection | KESC IEC 62282-3 |

| Efficiency | |

|---|---|

| Electrical efficiency @ BoL | ≥ 60% @ (LHV net AC) |

| Electrical efficiency @ EoL | ≥ 48% @ (LHV net AC) |

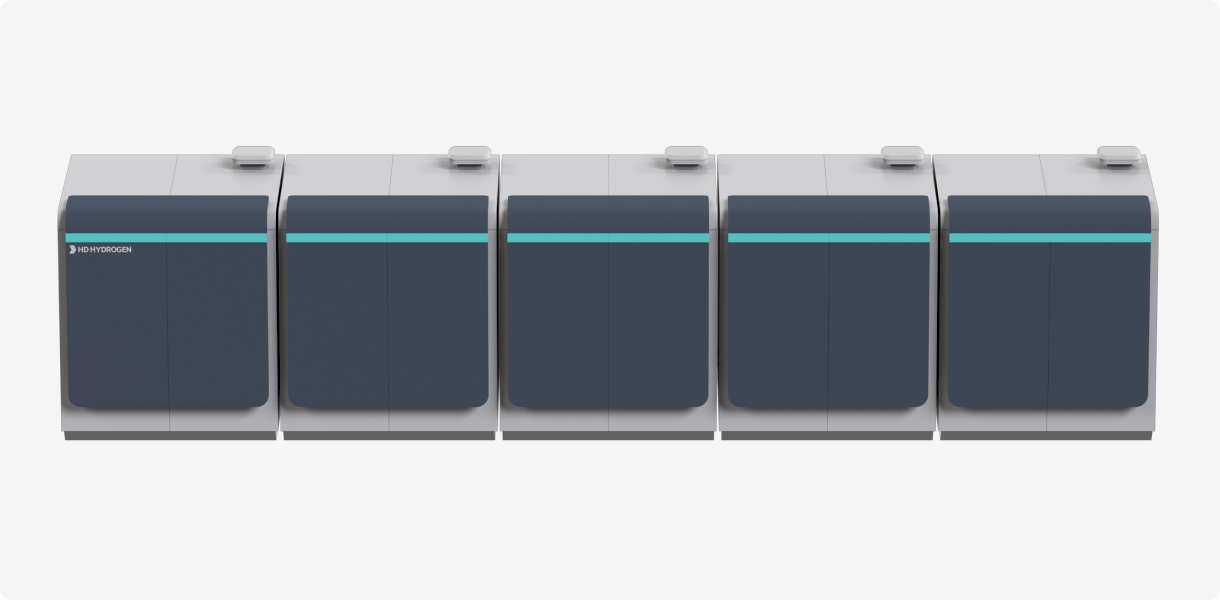

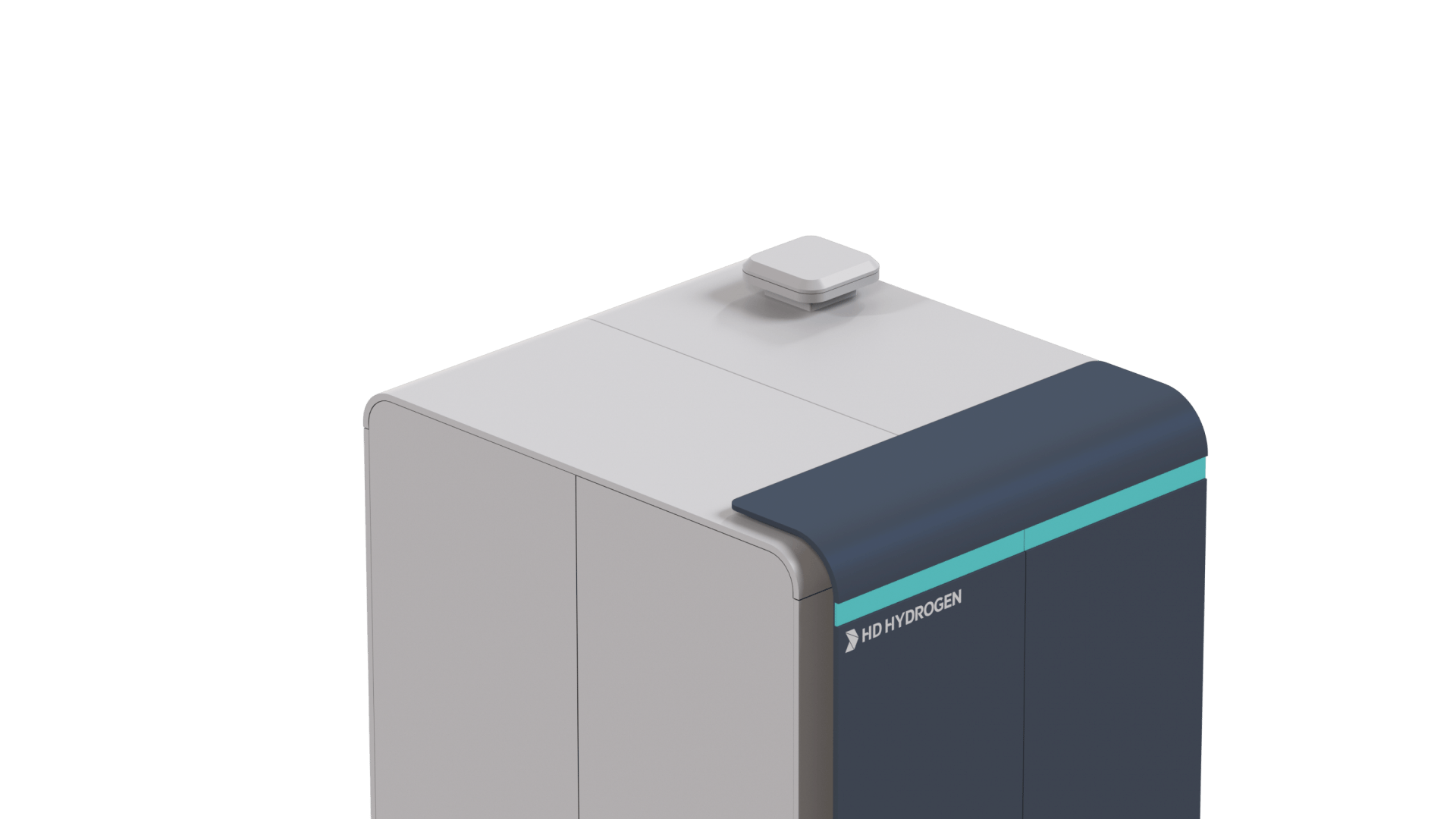

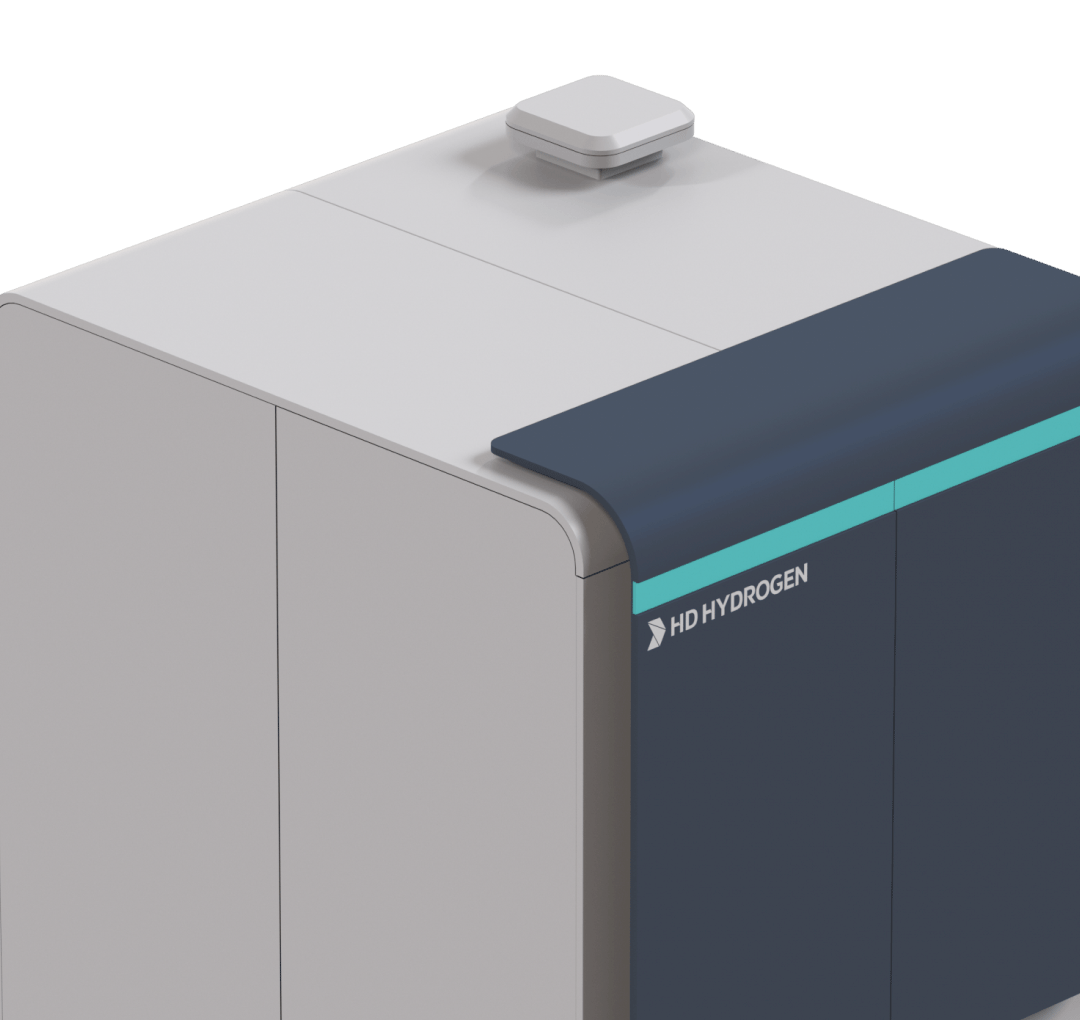

HD60 is a 60kW class product with a proven track record in various European projects. It embodies technological innovations in the Solid Oxide Fuel Cell (SOFC) field.

Like HD300, it offers high electrical efficiency, utilization of various fuels, and efficient and stable operation. Multiple HD60 units can be installed parallel to customer needs to provide power generation capacity that best matches customer demands.

Specification

| Outputs | ||

|---|---|---|

| Electric output | 60 | kW net-AC* |

| Thermal output** | 24 | kW (LHV, exhaust cooled to 55℃)* |

| Range of electric output | 60-30 |

kW (continuous modulation range 100-50%, in island mode, 0-100% |

|

Electrical efficiency at 50% output |

60 | % (LHV)* |

| Inputs | |

|---|---|

| Fuel supply pressure | 4 bar-g (+/-0.2 bar-g) |

| Fuel envelope, LHV |

440-850kJ/mol @ 25℃; equivalent to biogas compositions with 55-100%-mol CH4 with CO2 as a diluent |

| Nominal fuel intake | 10.7 Nm³/h (natural gas, ref. T=0 ℃, p=101,325 kPa) |

|

Fuel gas cleaning |

Built-in gas clean-up system is designed for removing odorants used in natural gas. Maintenance action required at 6-month interval. Applicability of biogas or special gases must be approved by Convion particularly with regard to sulphur, halogens or siloxanes. |

| Process air consumption | 470-670 Nm³/h |

| Physical Attributes and Environment | |||

|---|---|---|---|

|

Installation requirements for rated performance |

Elevation <15 m, -20…+40℃, outdoor installation. |

||

|

Electrical connection, capability |

3 × 380-440V AC, 50/60Hz, In accordance with local grid code |

||

| Noise level | < 70 | dB(A) at 1 m | |

| Water consumption | None | ||

| Exhaust gas | 200℃, 575 kg/h, dew point 37℃ | ||

| Heat recovery connection** |

Built-in heat exchanger hardware temperature limit is 120℃, 10 bar-g; actual water temperature shall be lower than the limit. |

||

| Exhaust Emissions | |

|---|---|

| Nitrogen oxides, NOx | ≤ 2.6 ppm-v/ ≤0.05 g/kWh (below detection limit) |

| Sulphur dioxide, SO2 |

≤ 3 ppm-v/ ≤0.07 g/kWh (below detection limit), Sulphur removed from fuel before use |

| Carbon monoxide, CO | ≤ 1.7ppm-v/ ≤0.02 g/kWh (below detection limit) |

| Particulates (PM) | Negligible |

| Volatile organic compounds | Negligible |

| Carbon dioxide, CO2 | 330 kg/MWhe |

| System Size and Weight | |

|---|---|

| Height | ~2330 mm |

| Length | ~2780 mm |

| Width | ~2090 mm |

| Weight | ~5900 kg |

| Efficiency | ||

|---|---|---|

| Electrical efficiency | 60 | % (LHV)* |

| Total efficiency | 94 | % (LHV) (exhaust cooled to 55℃)* |

- As quantified in reference ambient temperature 288,15 K (15℃) and pressure 101,325 kPa

- Heat recovery unit is an optional accessory

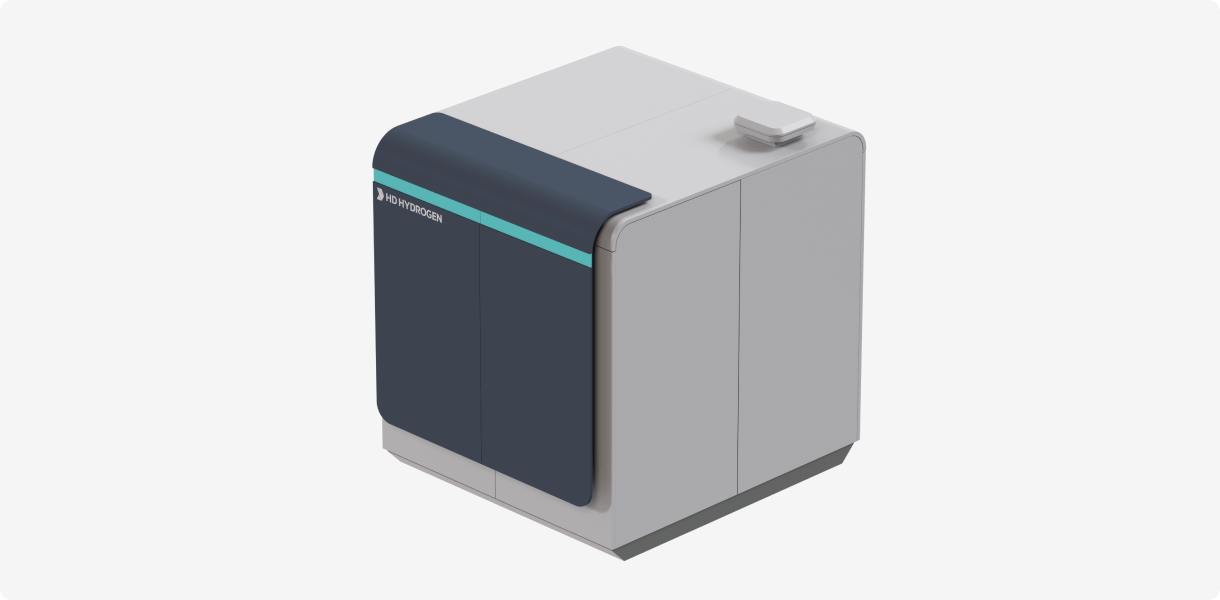

Solid Oxide Electrolysis Cell (SOEC) provides a solution for industrial decarbonization through efficient hydrogen production. HD250e is a modular steam electrolysis system that allows multiple units to be installed in parallel to achieve the desired capacity.

- Superior Efficiency and Economy

- Dramatically reduces energy consumption through high-temperature electrolyzer technology, more efficient than low-temperature electrolysis technology

- Flexibility

- Through rSOC functionality, switches to power generation mode when electricity prices are high, using hydrogen, biogas, or natural gas as fuel

- Carbon Capture and Utilization

- Produces syngas using CO2 as a co-feedstock

- Integration

- The HD250E system uses industrial low-pressure steam as feedstock, generated from waste heat and zero-carbon heat sources, reducing electrical energy requirements

Specification

| General Specification | HD250e | Unit |

|---|---|---|

| Power Connection | ||

| AC connection | 400 | VAC |

| Power intake | 249 | kW |

| Steam feedstock | ||

| Pressure | 2.5–4.0 bar-g | |

| Temperature | 200–250 | °C |

| Flow, self-regulated | 71 | kg/h |

| Product Gas | ||

| Hydrogen production | 6.4 | kg/h |

| Hydrogen fraction [1] | 80 | %-mol |

| Temperature | 200–350 | °C |

| Pressure | 1–30 | mbar-g |

| Sweep Air Exhaust | ||

| Oxygen content | 30–33 | %-mol |

| Temperature | ~200 | °C |

| Energy Performance | ||

| Electrolysis efficiency [2] | 85 | %-LHV |

| Steam consumption [3] | 11.1 | kg H2O / kg H2 |

| Power consumption | 38.8 | kWhe / kg H2 |

| Installation | |

|---|---|

| Ingress protection class | IP53 |

| Temperature [°C] | -20 … +40 |

| Altitude [m] | 0 … 1000 |

| Dimensions h*w*l [mm] | 3120*2090*2740 |

| Installation | Outdoor by default, indoor possible |

- Remaining content is steam and <1% N2 originating from internal leakages.

- Product gas LHV/electrical energy input, excluding energy required for steam generation.

- Utilization of steam in conversion; water recovery from product gas not accounted for